PETROL TANK

PETROL TANK.

Harley

883 Iron

In a team of 9 we chose to work on the Harley 883 Iron fuel tank.

To get started we took multiple photos of the tank, in

multiple angles, in Photogrammetry; a software which takes multiple photos of

objects and sticking them together to create a 3D model of the object.

After this stage the finished Recap is then exported in STL

file format and uploaded into Fusion 360 slicer to prepare the fuel tank

template patterns to be cut. These patterns are classified in X and Y axis to

make it easy to slot them into place (making the template model)

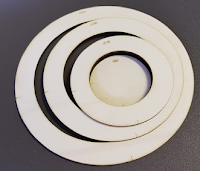

Using a laser cutting machine we cut out the model template

patterns (3mm thick plywood) and all its components at a scale of 1:1 after

previewing the model and making sure all the sizes/shape and scale are correct

before proceeding to cut. You don’t want to make a mistake before cutting

because it takes a long time for the laser cutter to cut all the pieces and

also since it’s a big class and not enough laser cutters, and the need to book

the machines you’re better off doing it correct at once.

After cutting the template pieces/components we assembled

the model.

Fig.1. Assembled models

And then after the assembling process is complete we glued the model together

using a hot glue gun. Followed by taping the model (after the glue dried) with

masking tape but didn’t complete that process because it would have taken a lot

of time… and a lot of tape (considerate of our resources as you can see).

Fig.2. Gluing the Model components together to avoid falling apart

So to overcome this we cut straight to the chase.

We taped A2 paper around the model and marked with a texta pen exactly where to

divide the model patterns that will later be traced onto aluminium sheets/skin

for our individual patterns/parts, which will enable us to shape the aluminium

skin to adhere to a third of the fuel tanks contours.

Fig.3. Taping paper template. Fig.4. Tracing paper template onto metal sheet

Now for the last part before everone starts their individual parts is to cut the metal(aluminium) sheets into the traced paper templates. We used manual sheet metal guillotine to cut out

the individual model patterns traced onto the aluminium sheet from the paper

templates.

Fig.5 Cutting traced template Fig.6. Cutting traced template

Using the english wheel to create bends and curves on my pattern/part (which is the whole left side of the tank and the top panel/pattern). this process is done slowly as the wheel is tightened to create

smoother edges.

i constantly checked after every minute or two of wheeling on the english wheel, i place my pattern on the designated position on the tank to see how much more work i need to do before i over-span the aluminium.

Fig.7. creating curves and bends using english wheel.

Fig.8. Constant checking of shape

I also used the sandbag, i shifted the sand to one side (angle) of the sand bag and placed the pattern at that particular angle and started hammering the edges using a egg shaped wooden mallet. Too much pressure is avoid when hammering (in all hammering processes) to avoid damaging the aluminium. ways this can happen include stretching, edges folding making it hard to bring them back to normal (total wreck!).

Fig.9. Using sandbag.

Fig.10. Contour marking/mapping

As advised by Russell, i drew contour lines (like those on a topographic map) around the top pattern to determine where to hit to create dip. a technic which was also used in making the bowl.

MY PATTERNS/PIECES:

Fig.11. Top Pattern (spray painted as finishing touch)

Fig.12. Left side

FINISHED PRODUCT:

FINAL PRODUCT (SPRAY PAINTED):

Comments

Post a Comment